My mod mania continues with a few performance oriented upgrades for the Boss. These are all designed to help the Boss manage heat while on the track.

1. Grille Mod

The original 1969 Boss Mustang deleted the front fog lights and replaced them with mesh to improve airflow to the radiator. The new Boss Mustang pays homage to this by also deleting the fog lights, but then replacing them with blanks that have been embossed with a non-functional mesh design. For a car with so much emphasis on function, this detail is out-of-step with the rest of the car. The Boss 302S and 302R race cars both replace the fog light blanks with actual mesh grilles. Furthermore, on hot days and at high revs on a race track, the Boss does have some heat management issues. So, the Boss could stand to have more air flow to the radiator. Even if that weren’t the case, I hate the fake grilles as much as I hate any other fake hood scoop, or the like. So, I drilled them out and made them functional.

Cost: Free!

2. Brake Cooling Ducts

2010-2012 MUSTANG BRAKE DUCT KIT – Ford Racing p/n: M-2004-MB

Contents of the kit.

The front bumper valence pieces were missing from the kit, so I had to call Ford Racing. I faxed my receipt and they sent the pieces out straight away.

The only difference is that the foglight blank is drilled-out.

The high-temp hose that comes with the kit does not fit around the backing plate duct. One solution is to modify the hose itself by cutting and/or removing the wire reinforcements within the hose. I wanted the hose to retain its full integrity, so I chose to cut the backing plate to allow the hose to fit. I don’t like cutting on brand new racing parts, so I had a Newcastle to take the edge off.

This is the backing plate after I modified it. Using a cut-off wheel, I made eight cuts into the duct and then bent the tabs slightly inward, which allows the hose to slide on easily. Then I painted the duct with high temp (1200 F) paint. The paint has a matte finish, so the texture should help the hose adhere to the duct.

Another thing Ford Racing didn’t get quite right were the installation instructions. First of all, the photos are so small and dark that they are almost useless. In the example I show above…I mean, I can see somebody’s meat hook, but what is it doing exactly? They don’t supply a list of tools needed, nor do they specify bolt sizes (although, they do provide torque specs which is very nice). They also recommend removing the whole lower front facia, which I think is completely unnecessary. Most importantly, the instructions are the bare minimum and do not address fitment issues which almost everyone will have, most notably, the interference of the horn assembly and the windshield washer fluid reservoir.

What follows are an alternate set of installation instructions. These instructions only apply to the Boss 302, WITHOUT the Laguna Seca splitter.

Tools:

- 7 mm socket

- 10 mm socket

- 12 mm socket

- 15 mm socket and/or wrench/ratcheting-wrench

- 13/16″ deep socket

- Dremel Tool with cutting wheel and/or hacksaw

- Small Phillips screwdriver

- Small flat-head screwdriver

- Paint scraper

- Sandpaper

- Bungee cord

- Jack and jack stands (or lift)

- Breaker bar

- Torque wrench

- Blue loctite

(See optional list below.)

Instructions for the Left (Driver) Side:

1. Jack up the car and secure with jack stands.

2. Remove the front wheel (13/16″ socket and breaker bar).

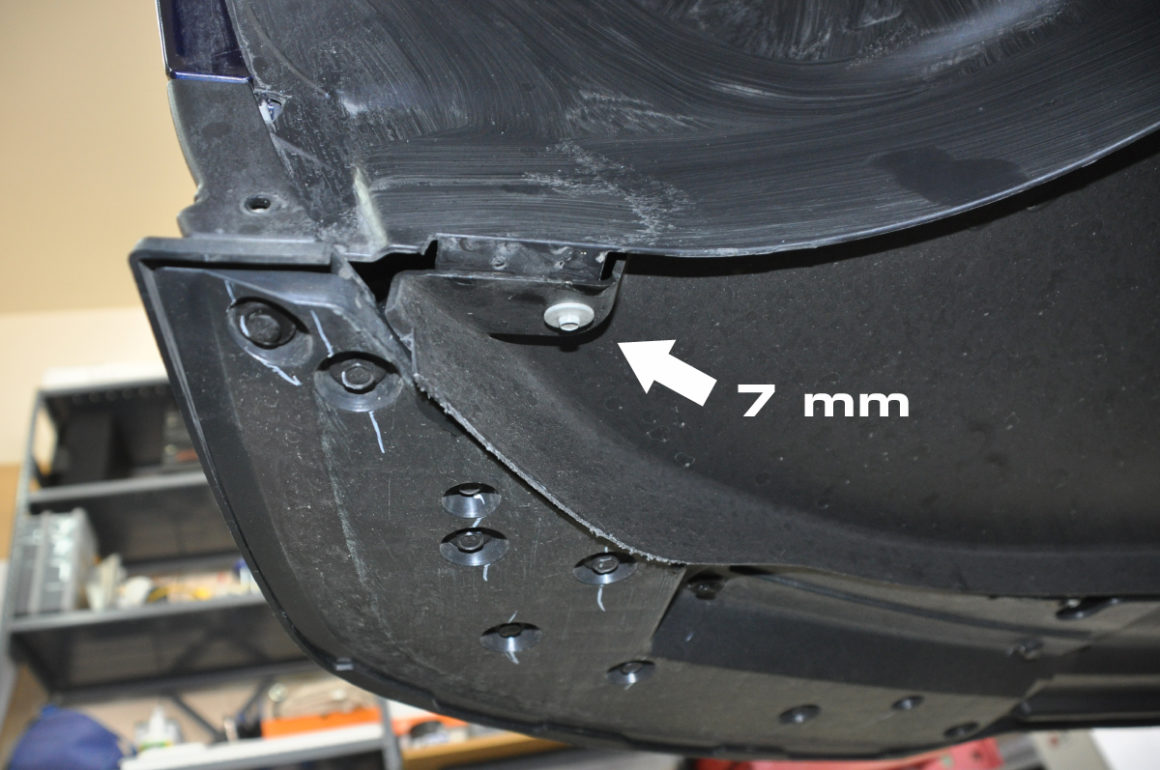

3. Remove inner fender liner. The fender liner is held on with (3) 7 mm bolts and several plastic push-style clips.

4. Relocate electrical harness. Just pull the harness holder from it’s current location and move it up to the hole indicated in the photo.

5. Relocate horns. In simple terms, this just means flipping the horn bracket 180 degrees to gain clearance for the hose. The correct way to do this for maximum clearance and to relieve stress on the electrical harness is to remove the horn assembly (one 7 mm bolt) and lay it on the undertray. Remove the (2) 8 mm nuts holding the bracket to the horns and turn the bracket 180 degrees. Then rotate the horns until the harness and connectors are in a position that will not cause interference with the hose and where there is no stress on the harness. Tighten down the (2) 8 mm nuts and then reinstall the horn assembly with the 7 mm bolt.

Remove the stock bumper valence piece, which can be done easily from the outside with a paint scraper (or similar). Insert a paint scraper behind the part of the bumper valence piece that is towards the middle of the car and use it to pry that side free. Simultaneously, pull on the inside of the foglight blank to free the other side (towards outside of car). The valance piece will pop-out easily.

Insert the hose from the front of the car and check for hose clearance. Also note in this photo that there is no reason to cut the foglight mounts. They do not in any way interfere with the hose. In fact, they fit perfectly against the hose and help secure it in place.

6. Remove brake caliper. Remove the (2) 15 mm bolts that hold the brake caliper to the brake carrier. Use a bungee cord (or similar) to support the weight of the brake caliper. I suspended the caliper from the front spring. Never allow the weight of the caliper to be supported by the brake line! This can cause a failure of the brake line, resulting in catastrophic brake failure!

7. Remove brake rotor. The rotor might have these retaining clips that keep the rotor snug against the hub when the wheel is off. I don’t know how to remove these properly, so I used a paint scraper, a flat-head screwdriver, and lots of swearing. After I worked them away from the rotor, I found I could rotate them off. I’m not a fan of unthreaded metal clips on my wheel studs, nor the risk of galling the threads while I am trying to work the clips off. If they were plastic, I would probably like them, but since they aren’t all that useful, I did not reinstall them.

8. Remove splash guard. Remove the (3) 10 mm bolts holding the splash guard to the brake carrier assembly.

9. Install the new backing plate with (3) new 12 mm bolts (included with kit) and torque to 15 ft.-lb.

10. Slide the brake cooling hose over the backing plate and secure with hose clamp (included with kit).

11. Secure hose to body with tie wrap (included in kit). Optionally, you can tie wrap the hose to the anti roll bar. Cut or grind down the plastic undertray shark fins that might cut or abrade the hose.

12. Cut excess hose length from front of car. Make sure there is enough free play in the hose to accommodate wheels turned to full lock (both directions) and the suspension at both full droop and full compression. You could skip this step until both sides are done and free play has been fully tested to your satisfaction. Install brake cooling hose to bumper valence insert and secure with hose clamp (included with kit). Push bumper valence insert firmly into place.

13. Cut inner fender liner to clear brake cooling hose. I followed a natural straight line that was in the liner, but it wasn’t quite enough and I had to make another cut to adequately clear the hose. This photo also gives a better view of my tie wrap point and how it holds the hose up off of the cut shark fin.

14. Reinstall inner fender liner.

15. Reinstall brake rotor.

16. Reinstall brake caliper. Apply blue Loctite and torque (2) 15 mm bolts to 85 ft.-lb.

17. Reinstall wheel. Torque (5) 13/16″ lug nuts to 98 ft.-lb.

18. Lower car and recheck all clearance points for interference and free-play.

Instructions for the Right (Passenger) Side:

Instructions for the left (driver) side of the car apply to the right (passenger) side of the car, except that instead of relocating the horn (Step 5), you might want to relocate the windshield washer reservoir. This requires some additional hardware (available at your favorite big box hardware store):

- (2) M6-1.0 x 50 mm bolts

- (3) 6 mm flat washers

- (1) 6 mm lock nut

- (2) 1/2 x .194 x 1″ nylon spacer (I had to drill these out a bit to fit the M6 bolts.)

- Drill

I recommend completely removing the windshield washer reservoir, installing the brake cooling kit, and then reinstalling the reservoir with new 1″ spacers. The reservoir is mounted to the car with (2) 10 mm bolts and (1) 10 mm nut that is attached to a removable stud. After removing the hardware, pull the washer pump straight up and out of the reservoir and remove the reservoir.

For the left side mount, first remove the stud by sliding it to the right and then pulling it out. From the backside, thread the new long bolt through the same hole, making sure that you use a washer to keep it from pulling through. Thread the nylon spacer onto the bolt, followed by the mounting tab of the reservoir. Secure with a washer and locking nut.

For the right side, thread the new long bolt (and washer) through the front of the mounting tab, then through the nylon spacer, and then tighten into the speed-nut that is in the factory mounting location.

For the upper mount, drill the upper mounting tab and secure using the factory hardware and mounting point. Press the washer pump back into the reservoir and refill.

This the location of the filler neck after the relocation.

Moving the windshield washer reservoir just 1″ allowed enough clearance for the brake cooling hose.

Test and Verify Fitment!

After a couple of days, I checked the fitment of the kit and discovered that on the right side, the wheel had come in contact with the hose and pushed it under a part of the body that then began to saw into the hose. So, I cut the tie wrap that secured the hose to the body, but left the hose tie-wrapped to the front sway bar. This allowed the hose to sit lower and avoid contact with the body. Things move around in there and it wouldn’t take much to destroy an expensive cooling hose, so go for a test drive and then verify that there is still adequate clearance.

Cost: $215

3. Transmission Cooling Scoop

Ford Racing p/n: M-5025-MBR (yes, it’s just a baking pan that has been welded to a steel dowel).

Installation requires removing the (4) 15 mm nuts that hold the rear support brace to the subframe. Replace the rear support brace with the cooling scoop. Install the (4) nuts and torque to 46 ft.-lb.

Cost: $95

4. Rear Splash Guard Delete

Ford Racing recommends removing the rear splash guards for better cooling of the rear brakes. Like the fronts, the rear splash guards are secured with (3) 10 mm bolts. Unlike the fronts, there is enough room between the rotor and the splash guard to fit a 10 mm wrench in-between to remove the bolts, so no need to remove the rear caliper. Remove the bolts, remove the splash guard, reinstall the wheel. Torque (5) 13/16″ lug nuts to 98 ft.-lb.

Cost: Free!

In an upcoming chapter, I will have a Boss 302R wing installed and painted.

Please pin, tweet, and share! Most importantly, let me know what you think in the comments below.