Time: 3 hours

Talent: Use of basic hand tools

Tools and Supplies: 30″ x 36″ sheet of Lexan, Anchor-Titeâ„¢ Marine Epoxy, 3M Safety Walk Outdoor Tread (2″ x 5 yd), utility knife, scissors, jigsaw with fine blade suitable for cutting Lexan, ruler, Sharpie, sandpaper, masking tape and duct tape.

Tab: $50

Introduction: The rear plastic window on my recently purchased 1997 Miata was torn in many places and was so sandblasted as to be almost opaque. I had no choice but to address this issue immediately. New rear panels (with new plastic or glass rear windows) are available, but these cost hundreds of dollars to purchase and have installed. I checked at Miata.net and found an FAQ (written by Mike Davis) describing an inexpensive fix which involves cutting out the plastic window and gluing in another piece of clear vinyl. I decided that there would be no harm in trying this inexpensive fix. If it didn’t work, I could always fork over the money for a professional repair.

The only major difference in my repair and the one described in the Davis FAQ is that instead of using clear vinyl to replace the window, I used a sheet of Lexan. Why? The main reason is because I already had a piece left over from when I made windows for my quattro race car. Also, I thought that the rigid Lexan wouldn’t have the problem of waves in the window from uneven gluing, as can happen with vinyl. Optically, the Lexan is certainly superior to vinyl, it is scratch resistant, and it is available tinted. Using Lexan means that all the materials in this FAQ are available at Home Depot, so there is no need to seek out marine shops or other sources for clear vinyl and other supplies. Finally, I’m not sure it has ever been done before, so…let’s get cracking.

Cat-Cat consulted on the project, but lack of opposable thumbs prevented some much needed help from him later.

Step 1: Prepare your work area. In the car, move and tilt both seats as far forward as possible. Unlatch the convertible top and unzip the rear panel. Lay the rear panel down on a board or other solid surface that is supported by boxes on the package shelf and/or the stress bar. If you have a fixed antenna, you might remove it for easier access to the work area.

Step 2: Using a utility knife or scissors, cut the rear window from the rear panel. Be careful not to cut into the panel. You can be conservative with the utility knife and then go back and easily clean-up with scissors. Don’t be too conservative, though – you will be using the old window as a template for your new window. You don’t want to be using a template that is too small.

Step 3: Tape the window to the piece of Lexan. Trace the outline of the window onto the Lexan, making sure to add 1/4″-1/2″ or so to the outside edge. This outside edge will be the surface that is glued to the rear panel on top of the old window frame.

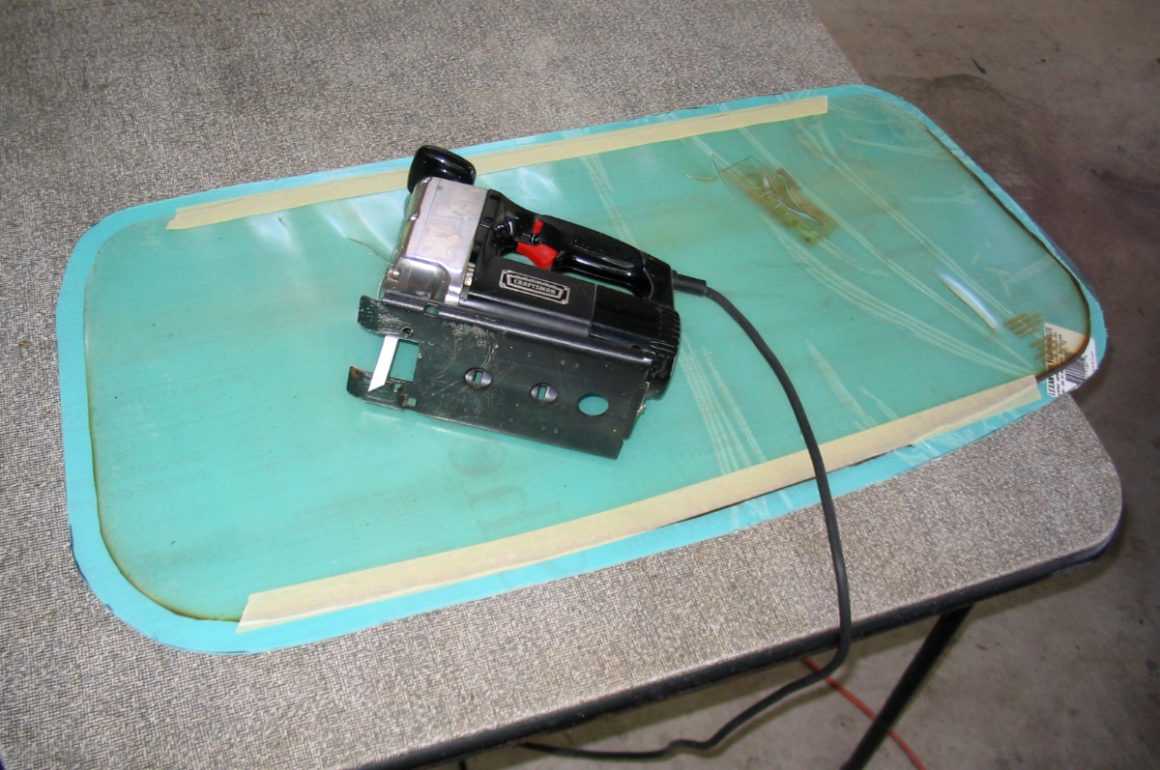

Step 4: Cut out the Lexan window. I used a jigsaw with a fine blade.

Step 5: Using the utility knife or an X-Acto knife, lightly cut and remove the protective sheets from just the outside 1/4″ of both sides of the Lexan window.

Step 6: Take a small sheet of sandpaper (I used 240 grit, but it doesn’t much matter), fold it over and scuff the outside edge of both sides of the Lexan window. This is to help with the adhesion of epoxy on one side of the window and tape on the other.

Step 7: Flatten and tape down the rear panel onto the support board to provide stability to the rear panel. It’s important to make sure that the base of the rear panel, which meets the bottom of the window, is pulled nice and tight with no slack in the material. You might pull it tight and then tack it to the support board. Mask off all of the rear panel, except for the raised outer frame left over from the old window. In fact, mask everything that you can. The epoxy is nasty stuff and you don’t want to have to try to clean it off of your nice convertible top.

Step 8: Mix the epoxy according to the directions. I chose Anchor-Titeâ„¢ (a Super Glue brand) Marine Epoxy. It has all of the specs I wanted for this kind of job: so water proof that it was designed for use under water, strong, flexible (nice for the frequent stretching of the convertible top), and a longer set time to allow for precise positioning of materials. I used two (2) 1 oz. packages ($5/ea).

Smurf Blood

Step 9: Apply the epoxy to the outside edge of the Lexan frame and to the left over frame from the old window, where it will join the rear panel. The epoxy is very thick and not so easy to work. I would recommend wearing nitrile gloves. This is where a helper really comes in handy. While you are applying the Smurf Blood, they can be cleaning up behind you if/when there is a spill. Another option is to have your helper do one piece and you do the other. This particular epoxy has a long set time, so don’t panic. Take your time and make sure there is good coverage on all of the contact surfaces.

Step 10: Position the new Lexan window onto the rear panel. A helper would helpful here, too. I would recommend making two tape-loop handles on the outside of the window, using duct tape or similarly strong tape. Use these handles to position the new window over the opening. I didn’t think of this until it was too late, so I was having to handle the window by it’s edges, which of course were covered in Smurf blood. *WARNING* Be advised that the base of the rear panel did not mate up to my new window! The window was cut correctly, but somehow, the window opening had deformed, perhaps because it was in the down and flat position. I’m thinking that my work surface might have been just a bit too low. For sure, the base of the rear panel was not pulled tightly enough. Among other things, this caused me to make a bloody mess of my car trying to get everything to meet in the middle. Later, when I zipped-up the rear panel, the base would not draw taut. It’s only a minor cosmetic issue, but an issue all the same. You can see the droopiness in the After photograph at the beginning of the article.

Oops

Step 11: Make an outer frame for the window using 3M Safety Walk Outdoor Tread, a 2″ wide black tread tape. The tape is heavily textured, but is still a good match for the original window frame texture. If you have been careful, you can probably cut down the tape, but I needed the full 2″ width to cover my sloppy work. The tape itself is pretty sticky, though not as much to itself, because of the texture. Time will tell how long the tape will last at all. It’s quite rigid and I’m concerned it won’t have the flexibility needed to remain stuck to the rear panel. Cosmetically, the material itself looks very good, but as you might expect, it still looks like a frame made out of tape. Ideally, one could get a sheet of this (or similar) material from an industrial safety catalog and make a nice, one-piece frame.

Conclusion: I must say that this inexpensive repair probably meets most of the major goals of the project: install a new rear window which is a) optically clear b) waterproof, c) inexpensive, and d) close to a factory appearance. For sure the window is clear and inexpensive. Time will tell if the installation is waterproof. However, the goal of having the new window installation appear to be close to a factory appearance was a failure, although it probably looks fine at 50-50 (50 feet and 50 mph). My material choices were good (especially the Lexan), but the tape can simply never make the grade. There should be a one-piece frame or it should be made from tape that is flexible enough to curve around the outside of the window in one piece.

That said, I think this is a worthwhile method of repairing a rear window on the cheap. Any disappointment I have has to do with my particular installation. I should temper my criticism by recognizing that the car is better now than it was before.

I will report the results of my long-term, road testing of this project, as well as any other modifications or adjustments to it.

This was posted to the Miata.net forums here.

Please pin, tweet, and share! Most importantly, let me know what you think in the comments below.

14 comments

I had the same problem using the lexan. I was wondering what they do when the have glass in them do they clear the bar ?

GREAT page on the Lexan window transplant.

2 easy questions:

Does Lexan go yellow over time?

Does it scratch easily?

Thanks for work you put into this page.

Allan

Zoltan – I still don’t know the answer to that question. The clearance isn’t even close and I really have to bend the window to clear the bar.

Allan – The Lexan has not gone yellow after almost three years on a car that is outside 24/7. However, it does scratch. Your comment has reminded me that people still read this FAQ, so I will do what I promised and report on the current condition of this project. The Lexan is pretty scratched-up, so I might try to polish out the scratches as part of my maintenance report.

Use novus #2 cleaner. it takesout the fine scratches of lexan. I buy it at my local Harley dealer.

I found your guide here http://forum.miata.net/vb/showthread.php?t=310188

I will attempt to do this with mine, since I bought my Miata with the soft plastic window torn from the zipper, but the rest is fine.

But what I’m wondering is why you put the Lexan on the outside rather than the inside. Is there an advantage to either way?

The stock Miata top (and most aftermarkets I assume) is designed to shed water into the rain rail and out through the sides of the body. Installing replacement windows (hard or soft) on the outside of the zippable panel forces any water to follow the same path with minimal problems of leakage into the interior. Installing the new window material on the inside of the zippable flap would require meticulous attention to the seal and even then would likely leak after a time as things flex and age. Not to mention it’s easier since it is the exterior surface of the zippable panel that is facing up when it is laying on the plywood work surface. 😉

Alright.. I’ve been searching all over the net for a way to replace my miata’s back window.. I’m really liking the idea of this and I plan on giving it a shot, one question though: Do you often put the top down and if so, does it put noticeable “bends” or dents in the window? Have you noticed that putting the top down affects the window?

Thank you for the excellent tutorial. I just finished a slight variation of your diy project and it can be found here http://sites.google.com/site/miatarearwindowrepair. One notable difference is that I did not create a transition (black tape) from the window to the convertible top. I just thought this might be interesting to you. Again, thanks for your original tutorial.

Great article.

So can you put down the top, without problems even with the lexan?

thanks again

+1 on the top down question

Sorry that I’m so bad about answering questions in a timely manner. Thanks for your comments!

Wink and Jim – I don’t know that I agree that a top-mount window would be easier to construct. If the vinyl window frame moves at all, when pressing the Lexan and epoxy down, there isn’t any way to nip, tuck, or easily make adjustments to the frame. You would have to pull the window up and try again. That makes for a big mess. As for being waterproof, it’s all about the epoxy and mine held for three years. I think I chose an inside mount, because I thought if done correctly (not my stupid tape idea), it would be cosmetically better. Honestly, if you can get a good seal, I can’t think of anything wrong with the outside mount window. If somebody does find it easier or better, please report your revision!

Danielle, Tsan, and Julian – Yes, I put the top down all the time. After I unzipped the panel, the window would rest against the rollbar. I would push down on the window, it would flex and then straighten-out, clear and out of the way, flat on the package shelf. However, it was under tension at the bottom (window/panel junction) and after three years, that’s where the vinyl finally split. I will also tell you that, especially at first, I was very rough with the window and panel. I figured that before I decided to go DIY, I was going to pay for a replacement anyway, so why not really put it to the test. I would slam it down and then just drop the whole convertible top down on top of it. Plop. Again, no problems for three years and then the vinyl finally split. Once it split, the epoxy finally gave way at the bottom and it started to leak. My solution? I bought a hardtop.

Joe – Thanks for the link. Congrats on your project!

I just completed replacement of the rear window on my ’90. I chose Optex from Lowe’s and used Loc Tite Vinyl Cement. I mounted mine on the inside. I left the origonal taped to the underside as a guide. I trimed with 1″ black Gorilla Tape both inside and out, cutting notches to turn the corners. It does’t look exactly origonal but it’s not bad. Thanks for the tutorial.

I just completed this process. I used Optex acrylic (like JJ Nelson) and a Dremel with the reinforced cutting bits to make the cuts (very accurate cutting/does not take a long as one would suspect). Also, per Joe Geyer, I used Goop Marine, which is clear and seems to be holding well.

Update: While parked in a parking lot on a very sunny day, the Goop Marine gave out on the top rim of the window. I have a black top, and it would seem the heat caused this. Mine was well sealed and both mating surfaces had been roughed up before application of the adhesive. The outside ambient temperature was probably 80°F. I drilled small holes and used a flat-headed bolt and nut to improve the strength on top, since it is not visible when the top is up anyhow. Just FYI.